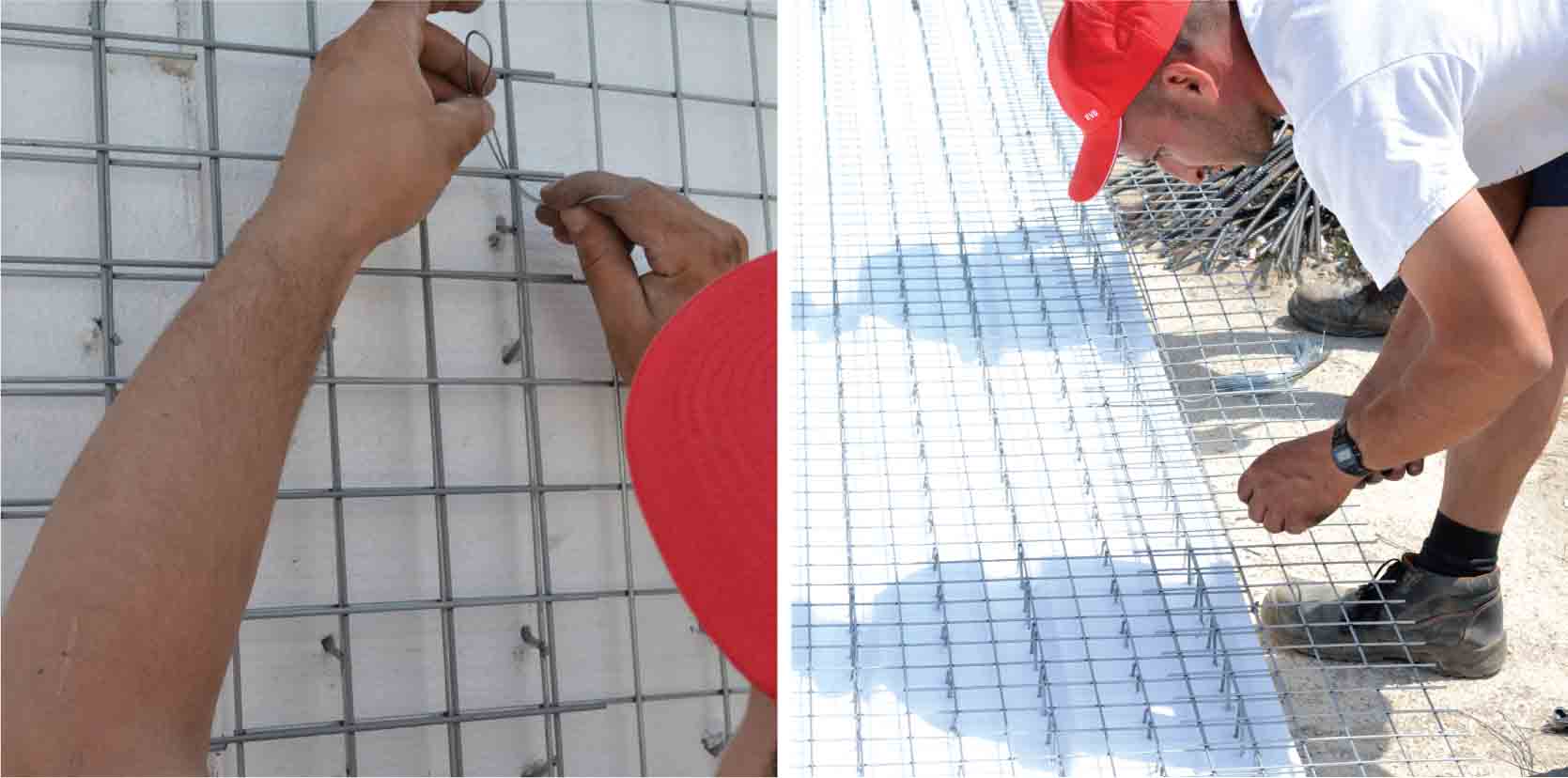

Erection of the NEGOCEPANEL panels always starts at corners, in order to achieve the required construction rigidity. Individual panels are connected together using a splice mesh on both sides, using either a manual or a pneumatic fastening tool.

Negocepanel International Limited

245 A Serena Conference Center Kampala Serena Hotel P.O. Box 71424 Kampala Uganda

+256 700 815964

Erection of the NEGOCEPANEL panels always starts at corners, in order to achieve the required construction rigidity. Individual panels are connected together using a splice mesh on both sides, using either a manual or a pneumatic fastening tool.

Panel walls are reinforced by means of splice mesh. This is normally required at corners, between panels and around openings. This will create continuous mesh reinforcement. Reinforcing ties and bars are used at building element junctions to add strength to joints. Meshes are tied together using pneumatic tools.

Openings for doors and windows can be easily cut on site to specific size as per details. Splice mesh is placed at each corner for consolidation. Extra re-bars are to be included for large openings. To reduce wastage, the panels remaining from an opening can be easily used as filler panels in the wall segment.

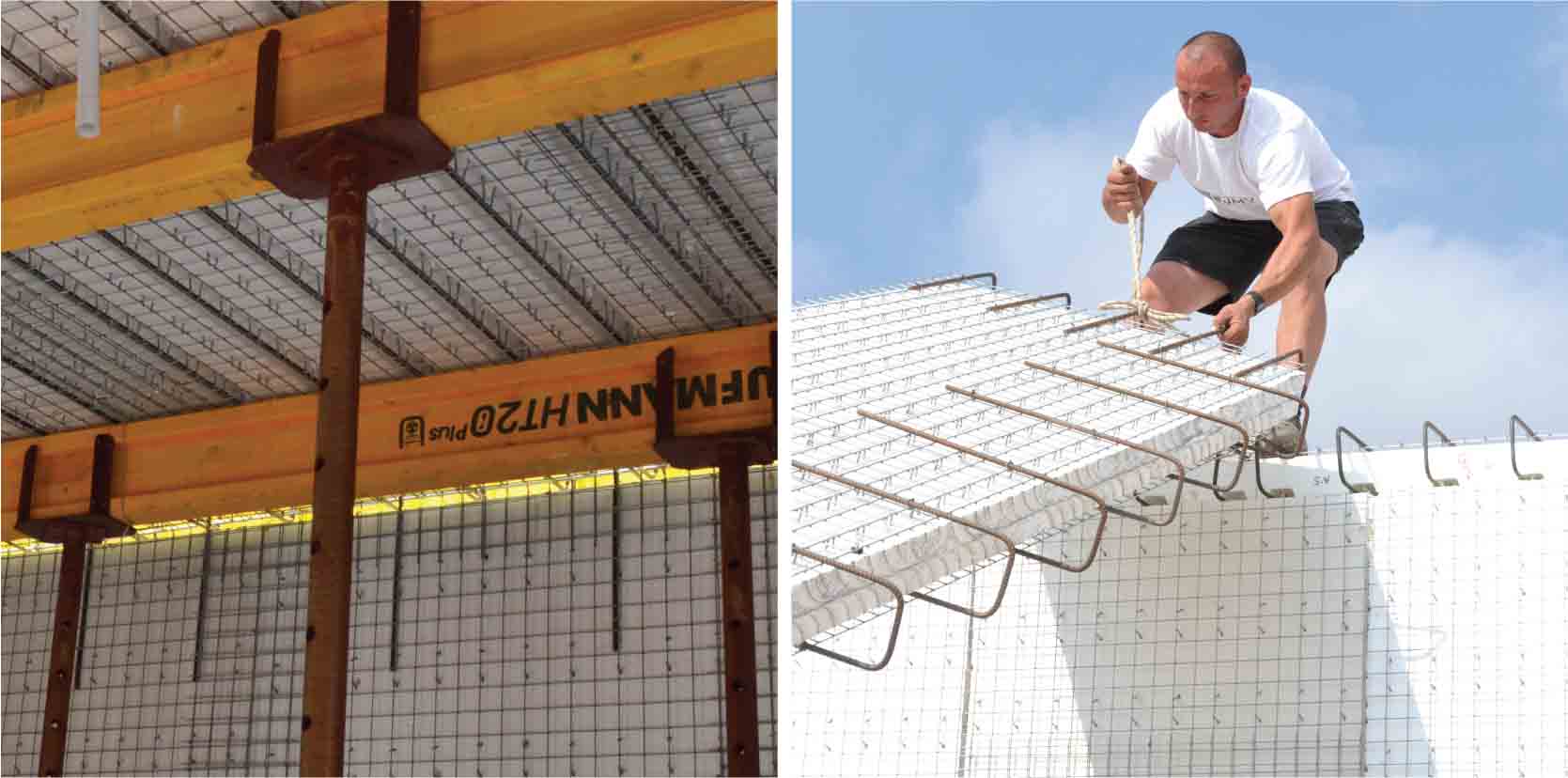

The NEGOCEPANEL panel system can be used for any roofs and floor slabs between storeys. Shoring is to be carried out using adjustable props with tripods and beams. Slab panels are reinforced with additional rebars at the bottom, U-bars at supports and splice mesh between panels. Slab panels are lifted manually and supported on the wall panels. This system could also be incorporated with traditional construction methods.

Another great feature of this system is the way it accommodates utilities. Once panels are secured in place, all services are passed between the reinforcing mesh and polystyrene. In order to increase this space, a propane torch or a heat gun may be used to melt the polystyrene.

Concrete is sprayed onto the walls and underside of slab using a shotcrete pump. Although, the normal procedure is to apply the shotcrete in two layers, the application may also be carried out in one single coat. Screed points of concrete are used as gauges to give correct concrete thickness and lines. Hand trowel finishing of the second layer is required to give the appropriate finish and surface tolerance.

Various finishes can be applied, both internally and externally.